The automated self-supporting storage system ensures product selectivity and high equipment availability. The stacker cranes in this system can be designed to work in single and double deep storage with telescopic forks or multi-deep storage with satellite vehicle. In this type of construction, the warehouse cladding is directly fixed to the storage structure, making masonry construction unnecessary.

The stacker cranes are equipped with high technology aimed at significant improvements for logistics processes. Designed to work in narrower aisles (compared to forklifts), they occupy less area and ensure aisle compaction. The system can be designed to work in single and double deep storage with telescopic forks or multi-deep storage with a satellite vehicle.

Due to its standardization and modularity, the system is expandable, allowing the client to add more equipment as they grow.

Equipped with a high-density system, the miniload stacker cranes are used for the handling and storage of smaller loads (up to 50kg), such as: boxes (plastic, cardboard, and metal) and trays (plastic and metal). These devices have higher handling capacity compared to pallet stacker cranes.

Scheffer’s satellite vehicle warehouses offer an efficient and innovative solution for handling and storing loads. Using advanced technology, our satellite vehicle systems optimize storage space, providing greater storage density and product accessibility. This results in faster and safer operations, meeting the demands of various sectors with high performance.

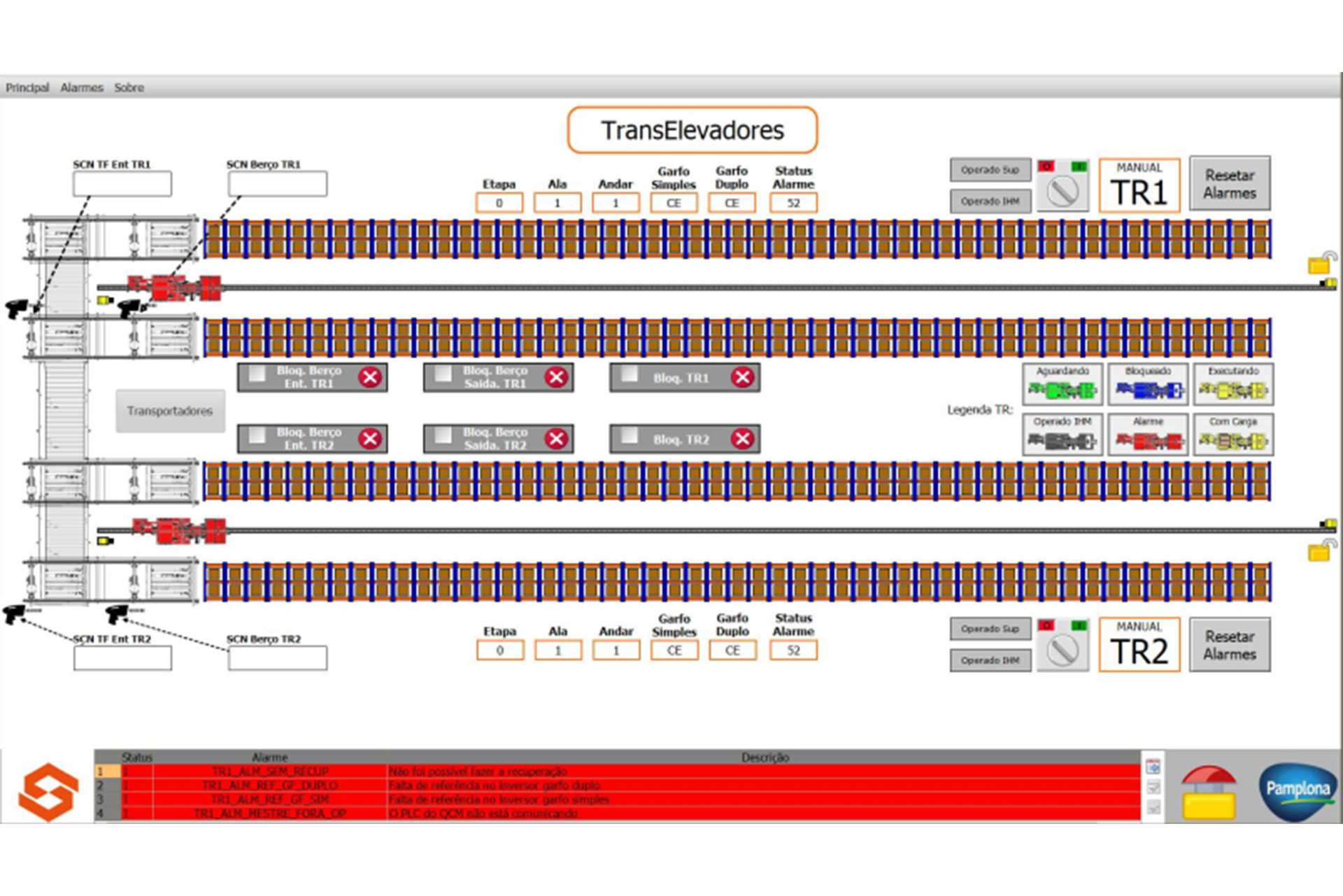

Scheffer’s warehouse management system is a robust and versatile tool designed to optimize all logistics operations within your warehouse. It allows for real-time monitoring and control of goods inflow and outflow, ensuring efficient inventory management. Our solution integrates seamlessly with other technologies and systems already in place in your company, providing a complete and detailed view of operations and assisting in strategic decision-making.